Perc Solar Cell Manufacturing Process

Perc solar cell manufacturing.

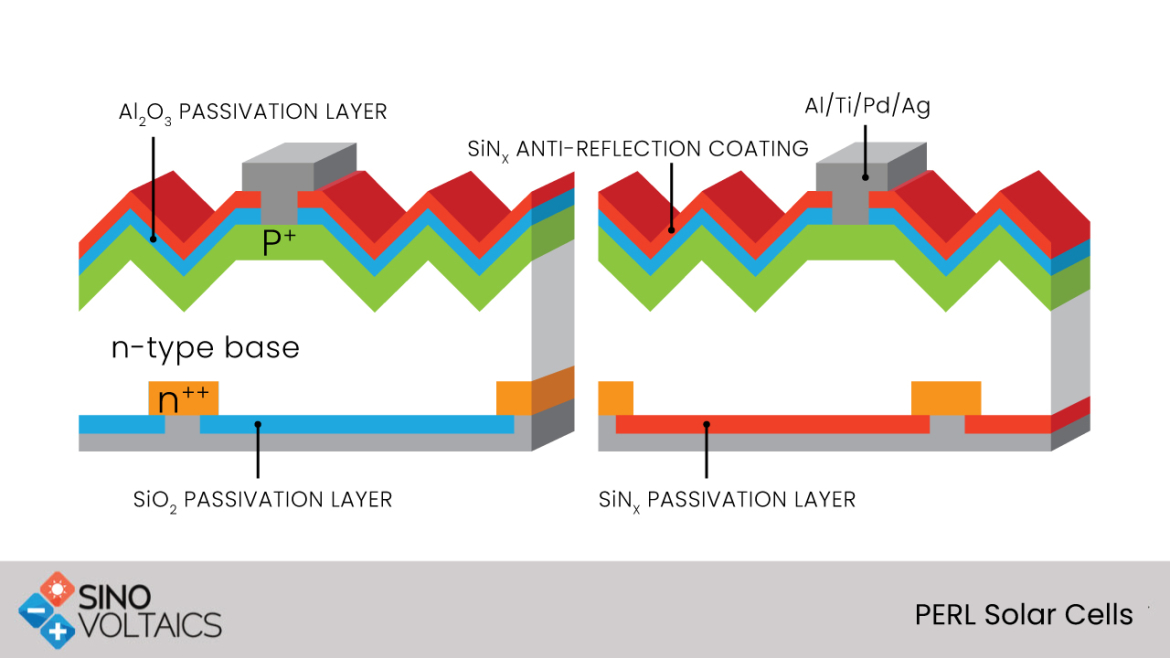

Perc solar cell manufacturing process. However from 2013 the industry is changing to the so called perc passivated emitter rear contact structure. The schematics of these two solar cells is shown in figure 1. Incorporating perc into a solar cell boosts generation. In order to create a.

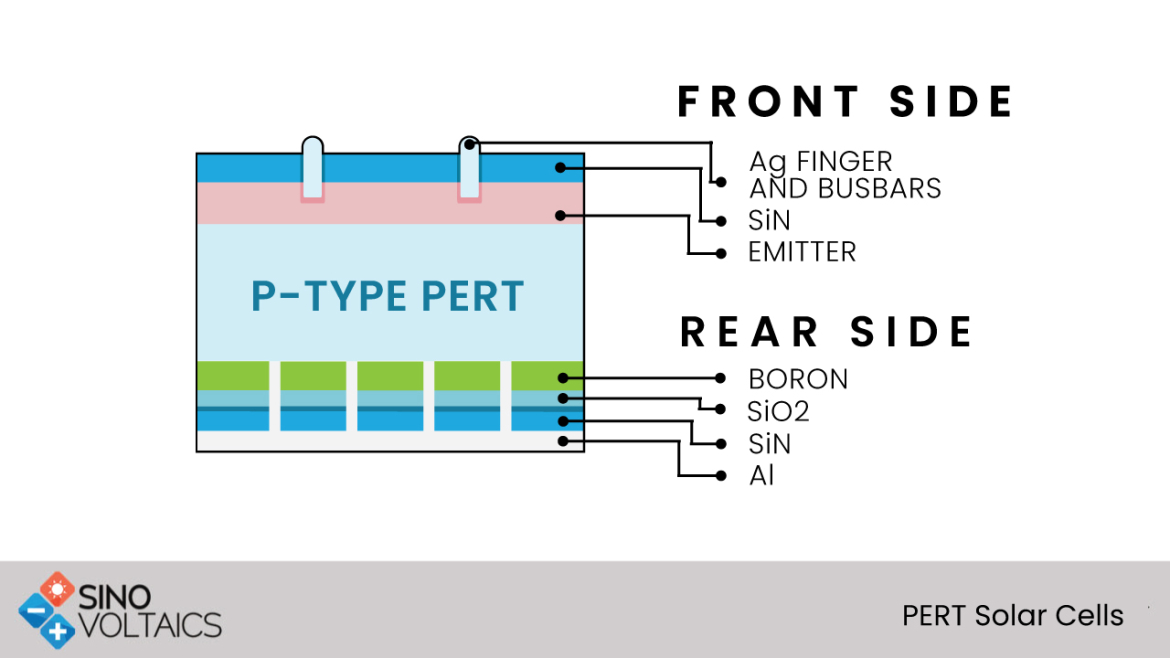

First a rear surface passivation film is applied. Meyer burger offers its customers modular coating systems for the production of perc solar cells. In principal incorporating perc into a solar cell boosts generation. The structure of a perc solar cell from front to rear.

Perc which stands for passivated emitter and rear cell or passivated emitter and rear contact is a new technology aimed to achieve higher energy conversion efficiency by adding a dielectric passivation layer on the rear of the cell. The aluminium back surface field al bsf solar cell has been the working horse for the photovoltaic industry in the recent decades. The main advantage of the perc cell structure is that it enables manufacturers to achieve higher efficiencies than with standard solar cells which are reaching their physical limits. The perc technology passivated emitter rear cell established by meyer burger in the global photovoltaics market represents the mainstream standard in solar cell production today.

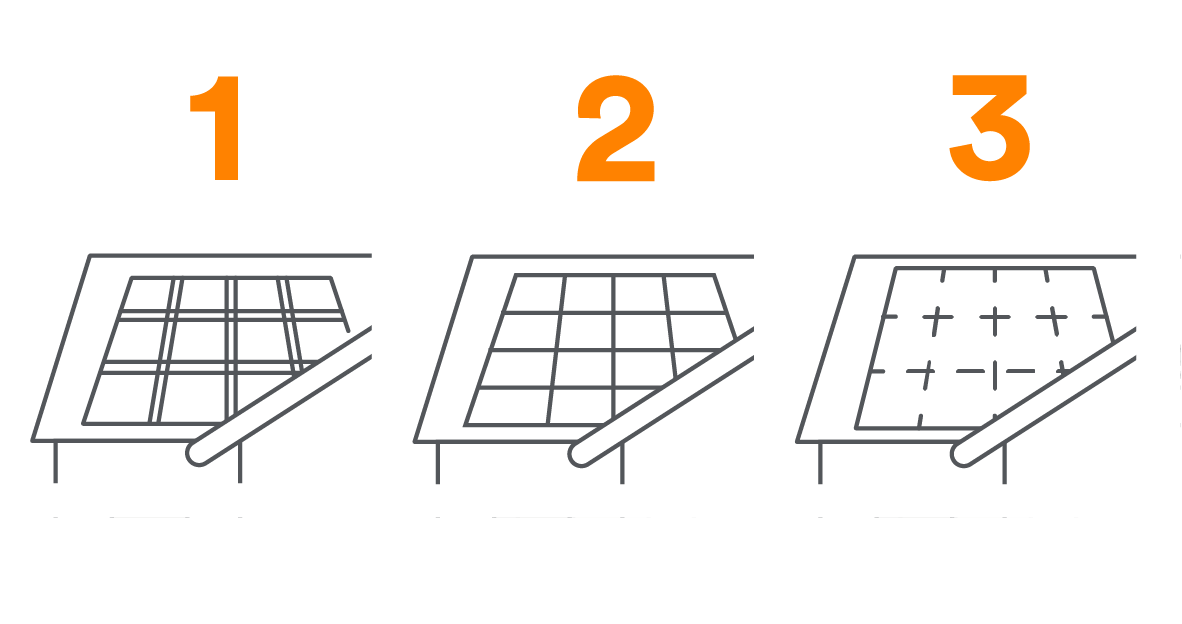

During 2019 production is forecast to exceed 60gw as the dominant technology type deployed by the solar industry for module assembly. Screen printed silver paste front contact. With the current state of the technology it is possible to achieve up to 1 absolute gain in efficiency. In order to produce a perc cell there are two additional manufacturing steps needed.

Back in 2014 p type mono perc cell production was less than 1gw. Perc technology adds an extra layer to the rear side of a solar cell.

.jpg)