Sheet Metal Bracket Design Considerations

It is always better to specify hole diameters that are greater than the sheet s thickness t.

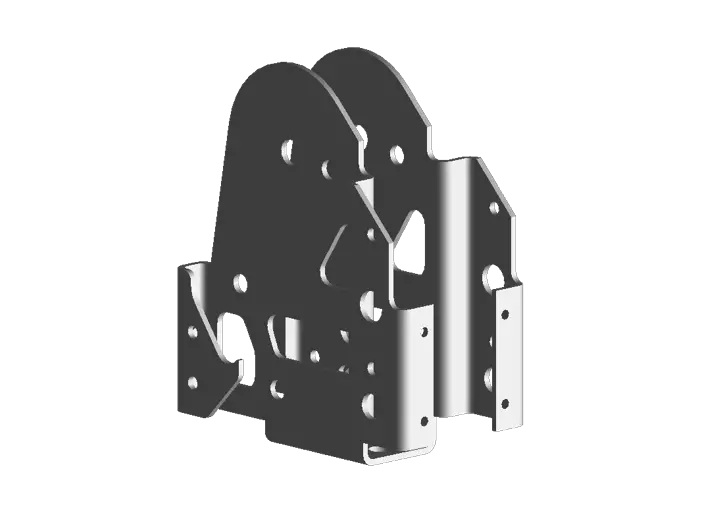

Sheet metal bracket design considerations. In a sheet metal design specifying hole sizes locations and their alignment is critical. Aside from that a variety of metals is available including stainless steel aluminum cold rolled and galvanized steel and even copper and brass in thicknesses ranging from 0 02 in. Sheet metal design series by design hub. Load carrying components or brackets constitutes an important role in the bus s engine room.

Learn practical sheet metal design with a strong theoretical understanding of underlying design principles. Currently he is working in the sheet metal industry as a designer. Learn more about protocase what we make who we work with our simple design processes and advanced design tools and our 2 3 day manufacturing process. Depending on the alloy.

Passengers on the bus. Select the dimensions of the metal sheet based the unfolded length of the bracket dimensions. He also likes to write articles related to the mechanical engineering field and tries to motivate other mechanical engineering students by his innovative project ideas design models and videos. Added 4 design projects mechanical design of simple sheet metal brackets using auto desk fusion 360 for specific problem statements.

Bending is a simple but limited method and the subsequent welding impairs the. The shape and dimension of your bracket will be determined by the shape of the item it is holding up but will also be affected by the load capabilities and the ease in manufacturing cost control. Sheet metal fabrication techniques. Learn sheet metal design processes and practical design considerations along with design projects.

Sheet metal by definition starts out flat but can be shaped in many different ways to meet many different requirements. Beyond sheet metal properties and available materials here are eight ways to improve sheet metal parts. While this paper focuses on the technologies that shape sheet metal by bending it along a single axis a variety of techniques exist for shaping. Mark the shearing line and bend line based on the specifications given in the bracket drawing.

With respect to the bendline fold or bent the sheet metal to the required shape ans size. The brackets are almost exclusively manufactured through bending and welding of sheet metal. Our customers are experienced sheet metal designers as well as engineers scientists and technologists who build electronics.