Shop Floor Control Company Goods

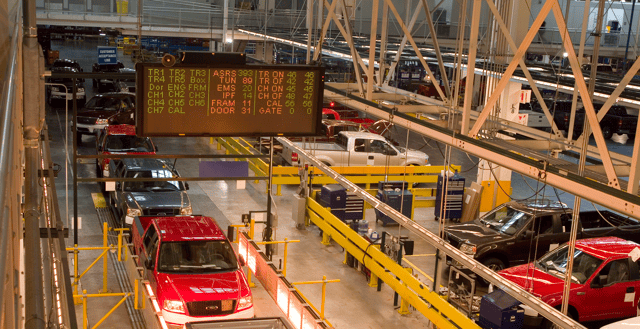

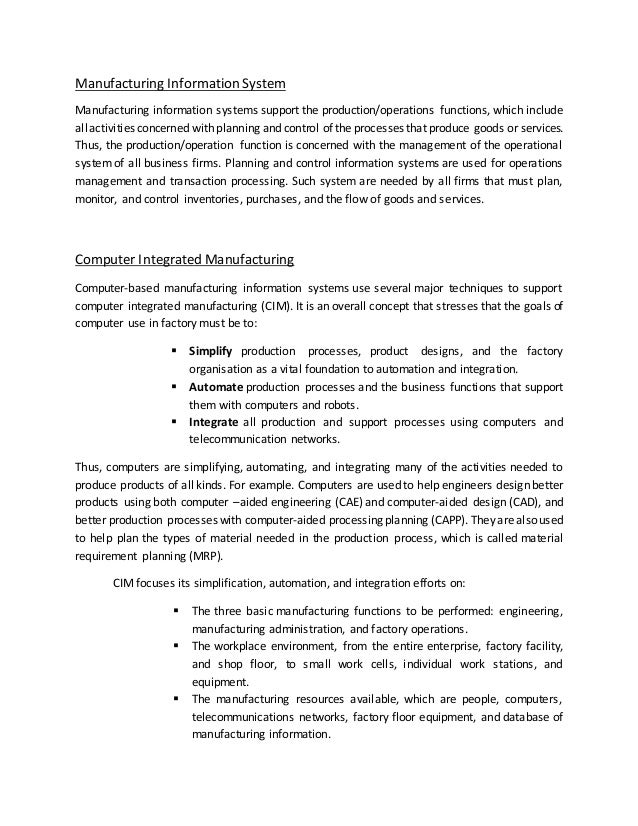

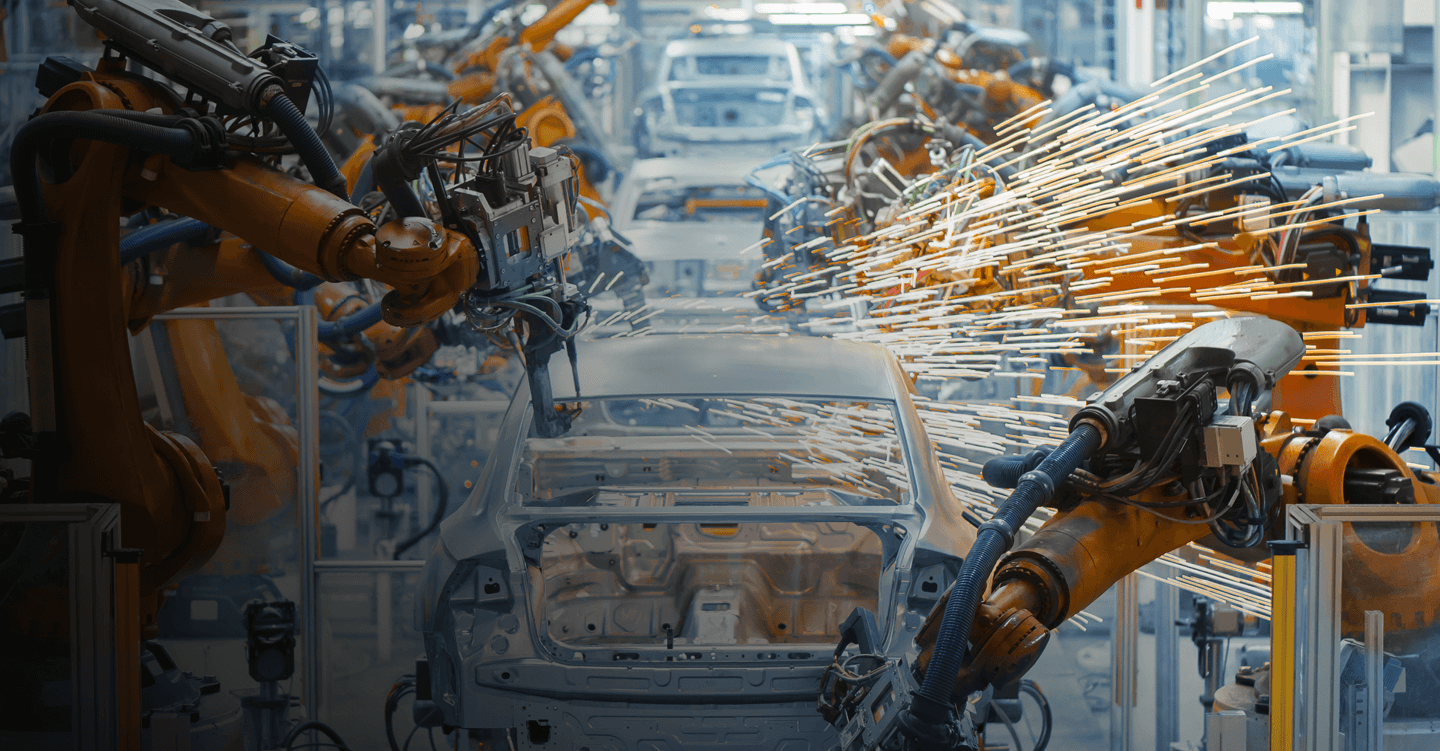

Shop floor control comprises the methods and systems to prioritize track and report against production orders and schedules.

Shop floor control company goods. Quality and production engineers gain a birds eye view of the production process improving quality and delivery timelines. Some of the most visible of these include. Store room it stores spare parts and other such inventories. Retrieval from shop floor operations and other such simulators.

Sampro s shop floor control software is the ideal solution for service operations that need the ability to assemble finished goods based on a bill of material. It allows you to manage and track manufacturing work orders processes and rate schedules. From the risk and security perspective the term shop floor control could also mean the process of identifying and assesing the vulnerabilities and the risks due to the environment people process and the technology at the shop floor level based on this assesment appropriate control measures are taken to keep the. Reliable inventory levels feeding the pipeline have to be established and a sound inventory system should be in place.

Integrate with current systems. The quality control section of a shop floor ensures that the product is flawless and up to the customer s satisfaction. Shop floor control sfc is a software system of methods and tools that are used to track schedule and report on the progress of work in a manufacturing plant shop floor control systems generally evaluate the portion of an order or operation that has been completed. An effectively managed shop floor control system serves as a mediator between production control and the shop floor.

Also known as open time this is the period of time allowed between processes so that all orders flow within your production line or service. The jd edwards world shop floor control system implements the material plan by managing the flow of materials inside the plant. That percentage of work in process is useful for resource planning inventory evaluations 1 and supervisor and operator. If there is an appropriate store room layout its management is shrewd and there are proper sops in place it will certainly reduce operational costs to quite.

Successful shop floor control demands broad real time visibility to track activities productivity and control costs. Availability of equipment and human resources. Real time shop floor control that plugs in to your erp plm bom payroll and production systems. Reinvent your shop floor by adding full visibility to your existing software and hardware systems.

When the product is ready it is required to undergo certain quality tests and criteria to meet customer satisfaction.