Shop Floor Control Pratices

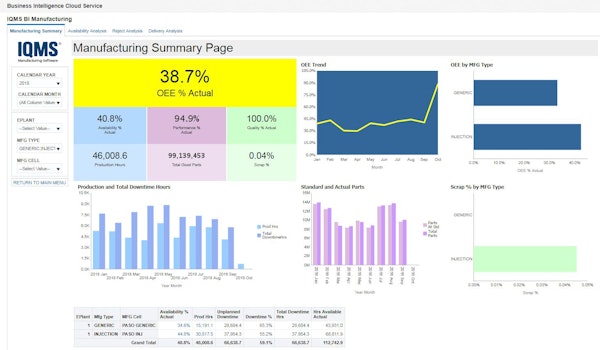

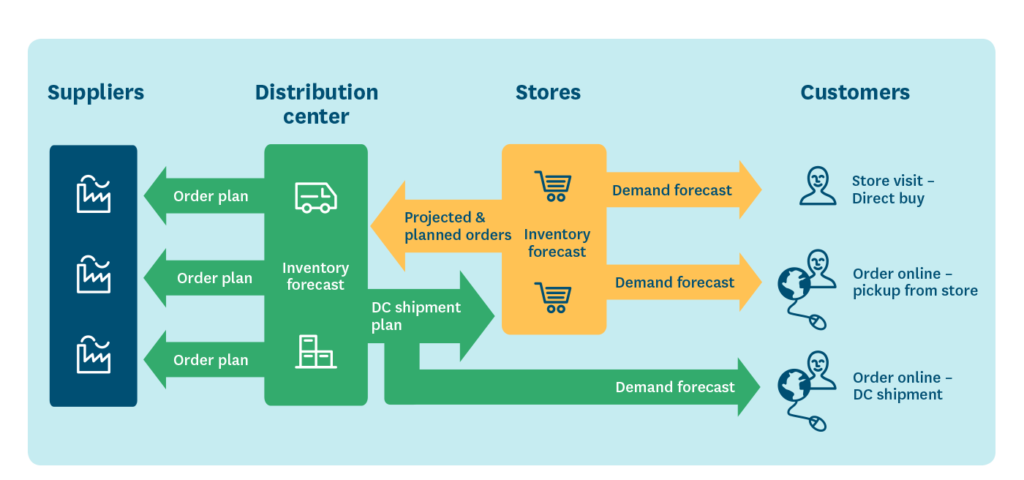

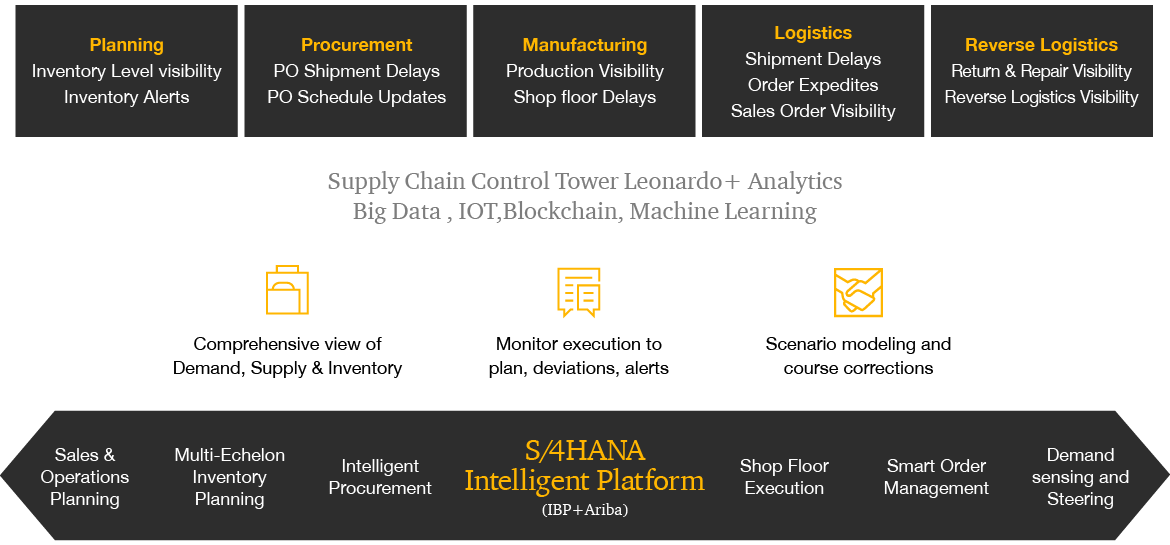

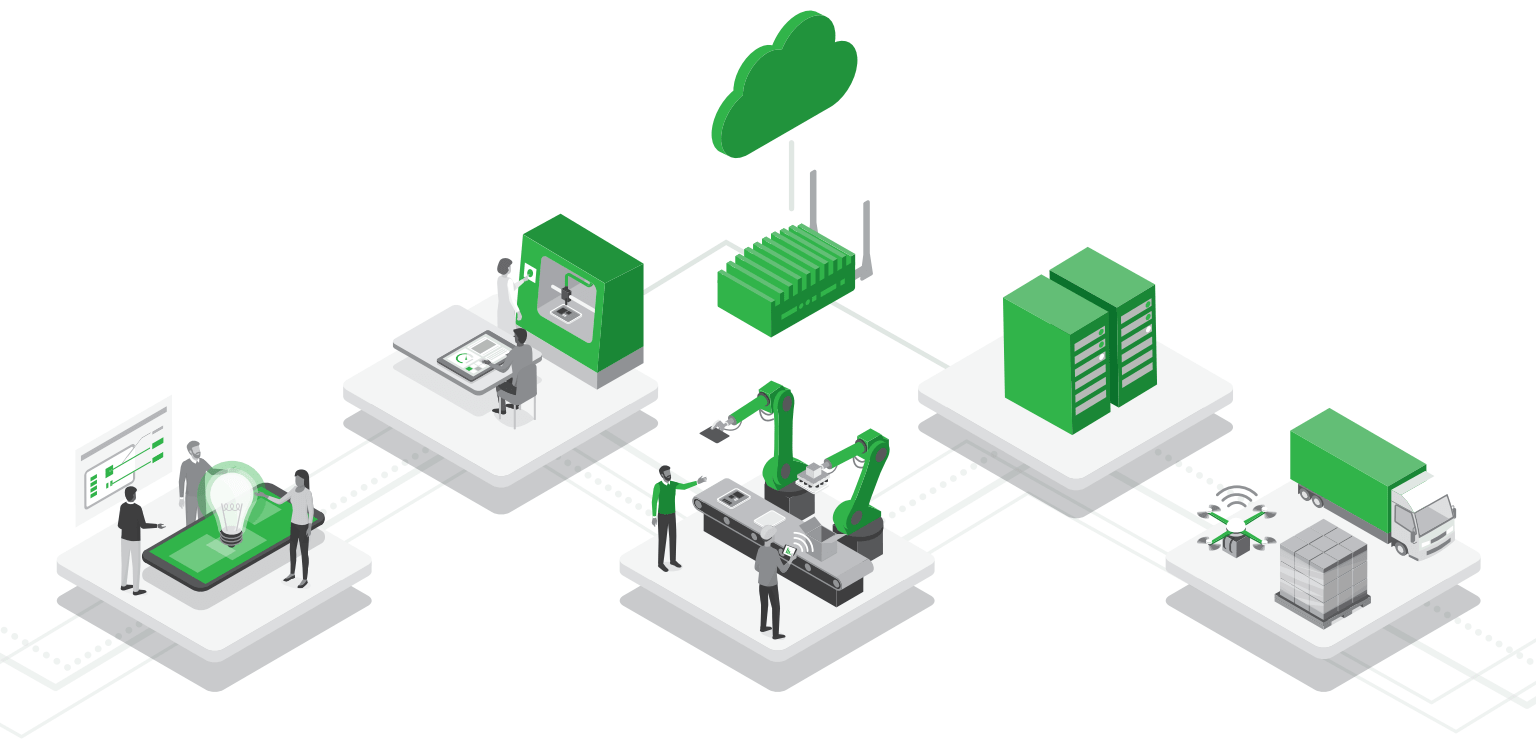

It includes the procedures to evaluate current resource status labor machine usage and other information required to support the overall planning scheduling and costing systems related to shop floor operation.

Shop floor control pratices. Shop floor control comprises the methods and systems to prioritize track and report against production orders and schedules. Agenda conventional best practices standardization lean work methods design 3. When the product is ready it is required to undergo certain quality tests and criteria to meet customer satisfaction. If there is an appropriate store room layout its management is shrewd and there are proper sops in place it will certainly reduce operational costs to quite.

An erp system has these capabilities and is flexible enough to accommodate changes. 1 order release 2 order scheduling and 3 order progress. A shop floor is the area of a factory machine shop etc. Shop floor control.

Shop floor control is concerned with ihe release of production orders to the factory monitoring and controlling the progress of the orders through the various work centers and acquiring current information on the status of the orders. A typical shop flour control system consists of three phases. An accurate schedule should be available not only to those in production planning but also to people on the shop floor who may be actively managing or producing product. 01 shop floor best practices 1.

Use technology to enhance production control. The dictionary definition of shopfloor at wiktionary. The quality control section of a shop floor ensures that the product is flawless and up to the customer s satisfaction. Store room it stores spare parts and other such inventories.

Where people work on machines or the space in a retail establishment where goods are sold to consumers the term shop floor is in contrast to office which is a space that provides accommodation to the business s management.

.png)