Shop Floor Control System Consists

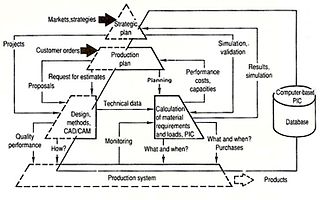

Shop floor control system shop floor control system phases phases input is collection of production plans eg.

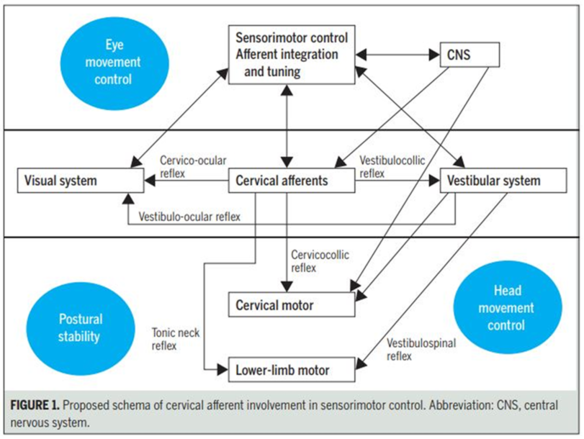

Shop floor control system consists. Shop floor control shop floor control is concerned with ihe release of production orders to the factory monitoring and controlling the progress of the orders through the various work centers and acquiring current information on the status of the orders. Frequent communication between scheduling and production issuing work to the shop floor with no material shortages. The jd edwards world shop floor control system implements the material plan by managing the flow of materials inside the plant. A good shop floor control system consists of.

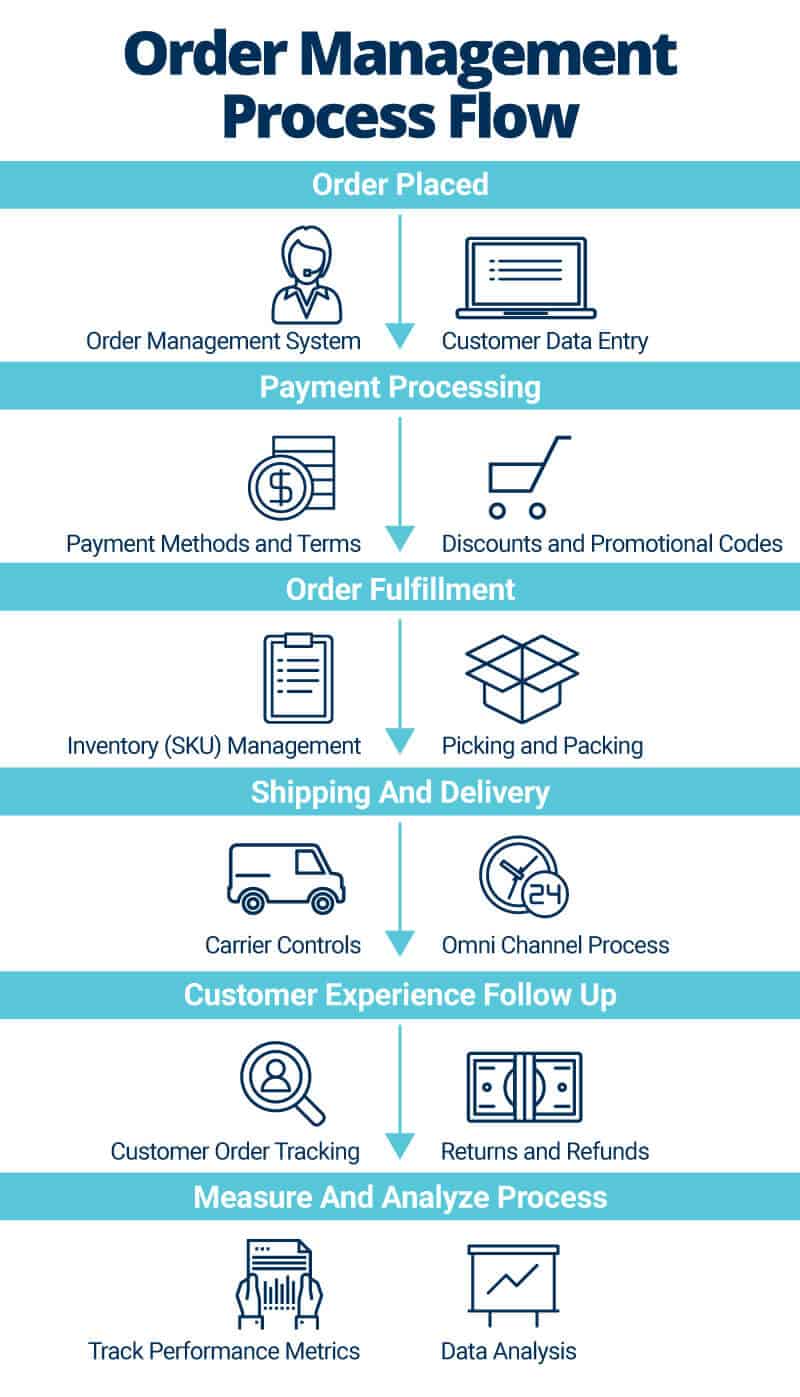

In the shop floor the real time system is used for production and inventory tracking and control. Shop floor control sfc systems are systems for managing the various components of the manufacturing process. Order release order scheduling order progress these phases are executed by a combination of computer and human resources. This type of tool is a major part of business process automation which industrial businesses are using to streamline workflows promote efficiency and improve revenue cycles.

Techopedia explains shop floor control sfc. An effectively managed shop floor control system serves as a mediator between production control and the shop floor. When a shop floor control process that is inadequate is supplemented with a state of the art shop erp the net result will be a faster yet inadequate shop floor control process. Shop floor control system in the apparel manufacturing for real time data the real time system is an it enabled system that can provide necessary information to its users as sooner as things are rolled on.

It allows you to manage and track manufacturing work orders processes and rate schedules. Results of process planning mrp capacity planning etc typical system consists of 3 phases. Shop floor control sfc is a software system of methods and tools that are used to track schedule and report on the progress of work in a manufacturing plant. Integrate with current systems.