Shop Floor Improvement Points

Chapter 8 br guiding improvement process at shop floor br think of small improvement fist br persuade someone to think about improvement br guide people to think about what they can do to improve br find ways to support and implement ideas br follow up the implementation br sharing success br if company have great success the.

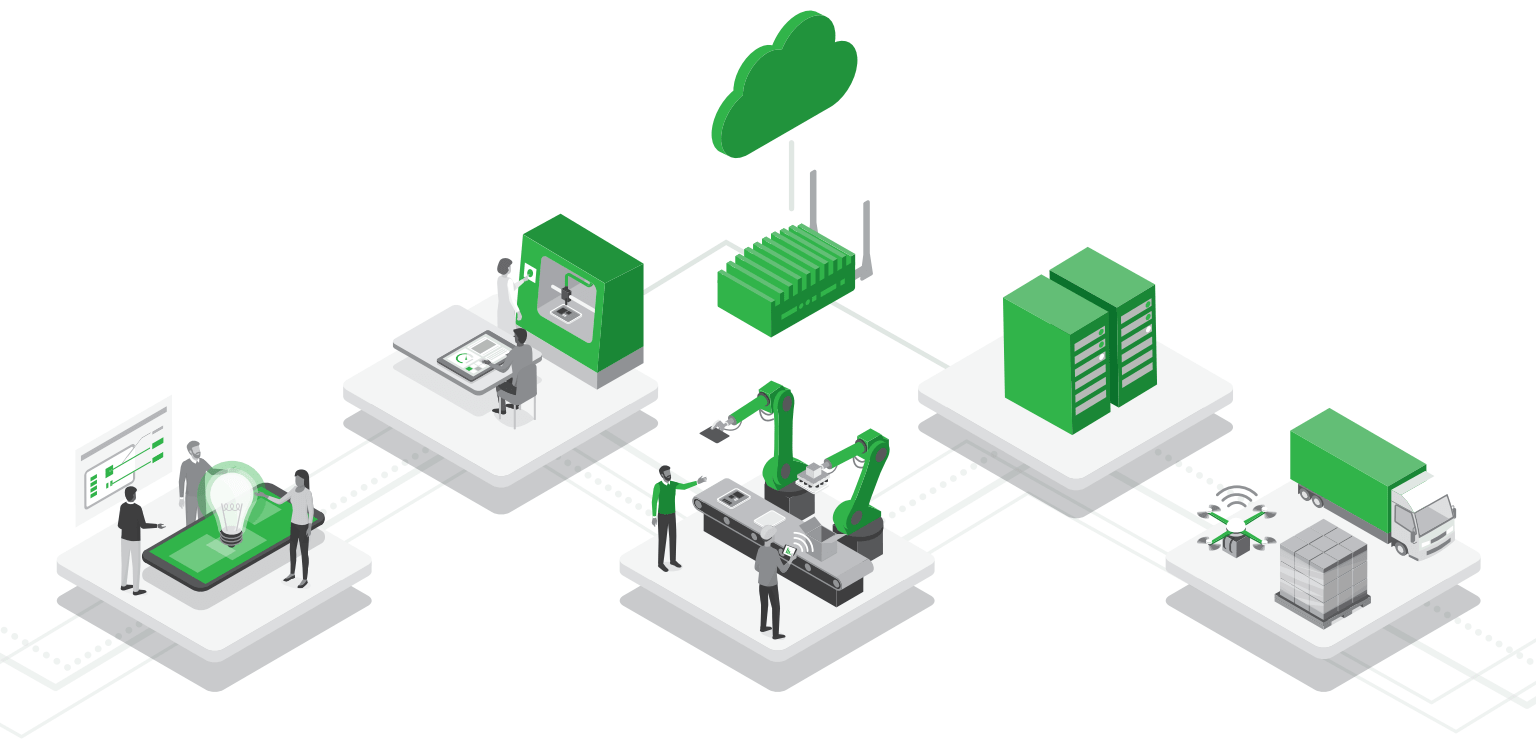

Shop floor improvement points. Many times this leads to improvements but only temporary improvement. The shop floor may include equipment inventory and storage areas shop floor is the place where design specifications are referred machinery and manufacturing equipment are employed for production parts are assembled or some raw material is processed. Shop floor is a part of machine tool industries. Truth is no initiative will have the immediate or profound impact on quality improvement that an mes or paperless manufacturing system does because the system offers the shop floor tools to improve quality and provides a sustainable foundation for process improvement.

It keeps electric equipment for various assembly types such as welding or soldering. Continuous improvement in all of these areas involves examining the current practices in place and making adjustments to systems employee training and even the equipment used to generate parts and components. Continuous improvement are crucial 3. The following departments work under a factory or a shop floor purchase department.

A shop floor keeps several sharp tools for cutting pressing filing fixing etc. The type of shop floor entirely depends upon kind of product manufactured the way a process is executed or the type of machinery used. It is a subset of the business enterprise where all the tangible production takes place. A shop floor is a small organization within a large one.

Every shop floor is different. As you might have guessed the mixed floor plan incorporates the straight diagonal and angular floor plans to create the most functional store design. The next generation shop floor management how to continuously develop competencies in manufacturing. 6 33 34 workers should collect.

However competency development internal and external is time. It is a solid layout for most any type of retailer. Productivity on the machine shop floor depends on a combination of efficient employees equipment and processes. The manufacturing waste due to overproduction over processing defects unengaged employees waiting time transportation inventory and.

Within a shop floor there are various smaller departments operations and responsibilities. Continuous improvement is better than delayed perfection. The layout moves traffic towards the walls and back of the store. A shop floor also has machines with running belts and wheels revolving shafts couplings spindles lifting and moving machines along with their attached moving parts.

It is something that adds no value.

/GettyImages-1186091457-1dfbcb081f6e4bcea9f8fdef15ba55ab.jpg)